- Home Page

- Company Profile

-

Our Products

- Profile Projector

- Hardness Tester

- MRP 1 Portable Hardness Tester

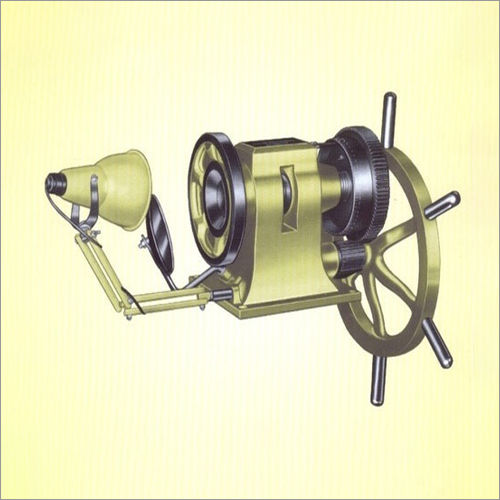

- Rockwell Brinell Hardness Tester

- Rockwell Cum Brinell Hardness Tester

- Rockwell cum Superficial Hardness tester

- Vickers Cum Brinell Hardness Testing Machine

- Digital Motorized Hardness Testing Machine

- TSM-DM Digital Motorized Hardness Testing Machine

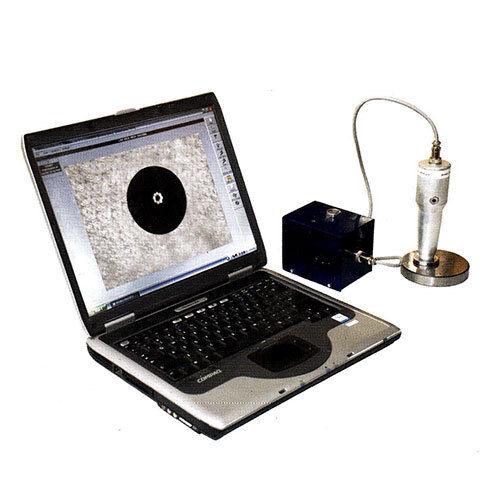

- Computerized Vickers Hardness Tester

- AKB - 3000 Brinell Hardness Tester

- OPAB - 3000 Optical Brinell Hardness Tester

- Digital-Computrised Micro Vickers Hardness Tester

- Brinell Hardness Tester

- Hardness Testing Machine

- Testing Machine

- Universal Testing Machine

- Dynamic Hardness Testing Machine

- Hardness Test Block

- Special Furnace

- Calibration Services

- Measuring System

- Servicing & Calibration

- Contact Us

Analog Cum Computrised Servo Universal Testing Machine

Product Details:

- Max Height 1600 mm (with Column)

- Operating Voltage 220V/440V AC

- Number of Specimens Single Specimen per Test

- Mounting Type Floor Standing

- Test Range Full range of machine capacity

- Automation Grade Semi-automatic, Computerized

- Response Time <10 ms

- Click to view more

X

Analog Cum Computrised Servo Universal Testing Machine Product Specifications

- 220V/440V AC

- Single Specimen per Test

- Floor Standing

- Full range of machine capacity

- 1600 mm (with Column)

- Laboratory/Industrial Material Testing

- Standard 25 mm test port

- 2% to 100% of Machine Capacity

- Semi-automatic, Computerized

- 10 kN, 20 kN, 50 kN, 100 kN, 200 kN (optional)

- <10 ms

- Analog & Computerized Servo Control

- 0.05 mm/min to 500 mm/min (Computer Controlled)

- As per Assembly Component Specification

- RS232/USB for PC Connectivity

- 500 mm

- 10C to 40C

- Tensile, Compression, Bending, Shear, Flexural Testing

- 0.01 kN (Load), 0.01 mm (Displacement)

- Approx. 1200 kg

- 50 Hz

- Universal Testing Machine

- Servo Control, Interchangeable Grips, Computer & Analog Operation, Overload Protection

- Varies with Fixture and Application

- Analog Dial & Digital PC Interface

- Up to 800 mm

- 1% of reading (As per IS 1828/BS 1610 Grade 1)

- Up to 90% RH, Non-condensing

- 220V/440V, 50Hz, 1/3 Phase

- IS, ASTM, DIN, BS

- Adjustable up to 800 mm

- Up to 800 mm

- AC Servo Motor Driven

- Industrial Grey/Blue

- Automatic data acquisition and storage

- Strain Gauge Type

- Overload, Over-travel, and Emergency Stop

- Hydraulic/Pneumatic/Wedge Type Grips Available

- <65 dB

- Windows-based UTM Software with Real-time Plotting

- Heavy Duty Steel Welded Structure

Product Description

Get the phenomenal Analog Cum Computrised Servo Universal Testing Machine, purpose-built for both laboratory and industrial material testing. Order this splendid equipment, available with industrial grey/blue heavy-duty steel construction and a redoubtable load cell strain gauge system. Procure precision with AC servo motor-driven control, supporting test speeds from 0.05 to 500 mm/min under analog or computerized servo modes. Featuring hydraulic, pneumatic, or wedge grips, robust safety features, and Windows-compatible UTM software for real-time plotting and data logging. Fully compliant with IS, ASTM, BS, DIN standards-this machine exhibits accuracy, versatility, and exceptional performance for tensile, compression, bending, and shear tests.

Application Versatility and Surface Suitability

The Analog Cum Computrised Servo Universal Testing Machine is engineered for laboratory and industrial applications, excelling on surfaces where tensile, compression, flexural, bending, and shear tests are essential. Its application surface covers metals, polymers, and composites, adapting to varied specimen shapes and sizes with interchangeable gripping systems. Application method is seamless-mount your sample using hydraulic, pneumatic, or wedge grips, set test parameters via analog or computerized controls, and commence testing with automatic data capture and precise control.

FOB Port, Export and Domestic Market Coverage

Supply of the Analog Cum Computrised Servo Universal Testing Machine is primarily managed via major Indian FOB ports for efficient international handover. We offer prompt delivery and comprehensive export services across Asia, Middle East, and Europe. Domestically, our main market focus is nationwide across India, offering traders, providers, and direct end-users exceptional support. On request, the machine is handed over fully calibrated, ensuring immediate operational readiness and seamless integration into your material testing regime.

Application Versatility and Surface Suitability

The Analog Cum Computrised Servo Universal Testing Machine is engineered for laboratory and industrial applications, excelling on surfaces where tensile, compression, flexural, bending, and shear tests are essential. Its application surface covers metals, polymers, and composites, adapting to varied specimen shapes and sizes with interchangeable gripping systems. Application method is seamless-mount your sample using hydraulic, pneumatic, or wedge grips, set test parameters via analog or computerized controls, and commence testing with automatic data capture and precise control.

FOB Port, Export and Domestic Market Coverage

Supply of the Analog Cum Computrised Servo Universal Testing Machine is primarily managed via major Indian FOB ports for efficient international handover. We offer prompt delivery and comprehensive export services across Asia, Middle East, and Europe. Domestically, our main market focus is nationwide across India, offering traders, providers, and direct end-users exceptional support. On request, the machine is handed over fully calibrated, ensuring immediate operational readiness and seamless integration into your material testing regime.

FAQ's of Analog Cum Computrised Servo Universal Testing Machine:

Q: How is the test process managed on the Analog Cum Computrised Servo Universal Testing Machine?

A: The test process is easily managed using either the analog controls or the Windows-based computerized servo system. Users set the required parameters, secure specimens with the selectable grip system, and initiate tests with automatic data acquisition and real-time plotting.Q: What safety features does this Universal Testing Machine provide?

A: This machine is equipped with overload, over-travel, and emergency stop features to ensure operator and equipment safety during all testing procedures.Q: Where can the machine be effectively used?

A: The equipment is suitable for laboratory and industrial environments, accommodating a wide range of materials, including metals, polymers, and composites for research or routine quality assurance testing.Q: When is calibration or servicing required for optimum performance?

A: Periodic calibration or servicing is recommended as per usage frequency and organizational quality policies, generally before critical test batches or annually, to maintain exceptional measurement accuracy.Q: What are the main benefits of procuring this Universal Testing Machine?

A: Users benefit from its high precision (1% accuracy), wide compatibility with global testing standards, real-time data logging, versatile grip system, and dual analog-digital operation for superior reliability and flexibility.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free