- Home Page

- Company Profile

-

Our Products

- Profile Projector

- Hardness Tester

- MRP 1 Portable Hardness Tester

- Rockwell Brinell Hardness Tester

- Rockwell Cum Brinell Hardness Tester

- Rockwell cum Superficial Hardness tester

- Vickers Cum Brinell Hardness Testing Machine

- Digital Motorized Hardness Testing Machine

- TSM-DM Digital Motorized Hardness Testing Machine

- Computerized Vickers Hardness Tester

- AKB - 3000 Brinell Hardness Tester

- OPAB - 3000 Optical Brinell Hardness Tester

- Digital-Computrised Micro Vickers Hardness Tester

- Brinell Hardness Tester

- Hardness Testing Machine

- Testing Machine

- Universal Testing Machine

- Dynamic Hardness Testing Machine

- Hardness Test Block

- Special Furnace

- Calibration Services

- Measuring System

- Servicing & Calibration

- Contact Us

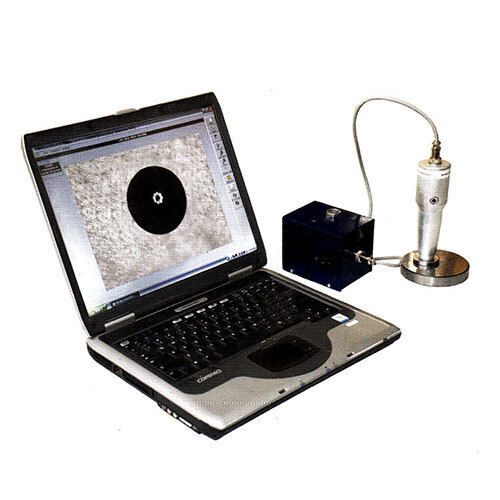

Brinell Impression Measuring system

Product Details:

- Power Supply 230V AC, 50 Hz

- Interface Type USB

- Mounting Type Desktop

- Equipment Type Brinell Impression Measuring System

- Application Measuring Brinell hardness indentation diameter

- Test Range 1 mm to 6 mm Brinell impressions

- Frequency 50 Hz

- Click to view more

X

Brinell Impression Measuring system Product Specifications

- 0.01 mm

- Automatic fast scanning

- 2.5 kg

- Up to 1000 readings storage

- Non-contact optical measurement, report generation, data storage

- 0.01 mm

- 5-inch TFT Touch Screen

- USB 2.0

- Impression size: 4 mm 7 mm

- Brinell hardness test measurement

- <1 second

- Measures Brinell indentation

- Semi-Automatic

- Operating: 10C to 40C

- Up to 90% RH, non-condensing

- USB

- Desktop

- 230V AC, 50 Hz

- Digital control via touchscreen

- 230V AC

- 1 mm 6 mm

- 50 Hz

- Supports multiple indentations

- 1 mm to 6 mm Brinell impressions

- 4 mm to 7 mm impressions

- Brinell Impression Measuring System

- Measuring Brinell hardness indentation diameter

- Internal memory for storing up to 1000 tests

- Real-time image processing for auto edge detection

- Windows 7/8/10

- USB cable, calibration standard, user manual

- Support for standard Brinell indenters (2.5 mm, 5 mm, 10 mm)

- White/Blue

- High-resolution digital camera (5 MP)

- PC application compatible; data export in Excel/CSV format

- <25 W

- LED illumination for clear impression capture

- Automatic calibration facility provided

- 220 mm × 180 mm × 100 mm

- IP20

- Meets ASTM E10, IS 2281-2005 standards

Product Description

Introducing the Brinell Impression Measuring Systema remarkable solution for precise Brinell hardness tests. Equipped with a high-resolution 5 MP digital camera, this monumental device utilizes the latest real-time image processing and LED illumination to ensure enviable accuracy for measurement. Select automated calibration and rapid touchscreen controls for seamless testing. Export data effortlessly to Excel/CSV, store up to 1000 readings, and benefit from digital control. The system complies with ASTM E10 and IS 2281-2005 standards, making it a trusted promotion for advanced material testing across service providers, suppliers, and traders in India.

Versatile Application and Competitive Advantage

The Brinell Impression Measuring System, ideal for use on metallic surfaces, excels in measuring Brinell hardness indentation diameters ranging from 1 mm to 6 mm. Its advanced non-contact optical technology and automated calibration provide a significant competitive advantage, reducing operator subjectivity and increasing reliability. Real-time edge detection and rapid data export make it suitable for applications in research labs, quality control departments, and routine industrial processes, enhancing productivity and consistency across various testing media.

Supply Ability and Timely Dispatch

Benefit from reliable supply ability and streamlined deliveries for the Brinell Impression Measuring System. With competitive sale price and transparent list price options, orders are promptly dispatched from major FOB ports in India. The system is typically available for delivery within 1 to 2 weeks, subject to stock availability. Service providers and traders can count on consistent inventory and dependable shipping timelines for their purchases, enabling efficient project planning and uninterrupted testing operations.

Versatile Application and Competitive Advantage

The Brinell Impression Measuring System, ideal for use on metallic surfaces, excels in measuring Brinell hardness indentation diameters ranging from 1 mm to 6 mm. Its advanced non-contact optical technology and automated calibration provide a significant competitive advantage, reducing operator subjectivity and increasing reliability. Real-time edge detection and rapid data export make it suitable for applications in research labs, quality control departments, and routine industrial processes, enhancing productivity and consistency across various testing media.

Supply Ability and Timely Dispatch

Benefit from reliable supply ability and streamlined deliveries for the Brinell Impression Measuring System. With competitive sale price and transparent list price options, orders are promptly dispatched from major FOB ports in India. The system is typically available for delivery within 1 to 2 weeks, subject to stock availability. Service providers and traders can count on consistent inventory and dependable shipping timelines for their purchases, enabling efficient project planning and uninterrupted testing operations.

FAQs of Brinell Impression Measuring system:

Q: How does the Brinell Impression Measuring System achieve accurate measurement?

A: The system employs a high-resolution 5 MP digital camera and real-time image processing for automatic edge detection of Brinell indentations, ensuring measurements with accuracy up to 0.01 mm.Q: What kind of surfaces and applications can this system be used for?

A: It is designed for use on metallic surfaces and is ideal for measuring Brinell hardness indentation diameters in materials testing, quality control, and research laboratories.Q: When can users expect product delivery after placing an order?

A: Orders for the Brinell Impression Measuring System are typically dispatched within 1 to 2 weeks from major ports in India, depending on stock availability.Q: Where does the system store test data and what formats are supported for export?

A: The system has internal memory capable of storing up to 1,000 test results, with data export options available in Excel and CSV formats for easy reporting and analysis.Q: What is the process for calibration and test measurement?

A: Automatic calibration ensures the system is ready for use with standard Brinell indenters. The touchscreen display guides users through digital control processes, enabling rapid and precise test measurements.Q: How does the system benefit service providers or traders in India?

A: It delivers monumental convenience and remarkable efficiency in hardness testing, ensuring reliable results, fast scanning, and easy data management, which are crucial for service providers, suppliers, and traders.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free